LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

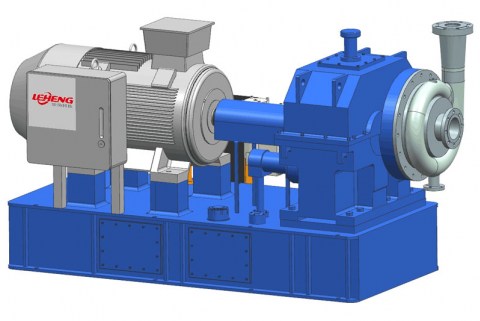

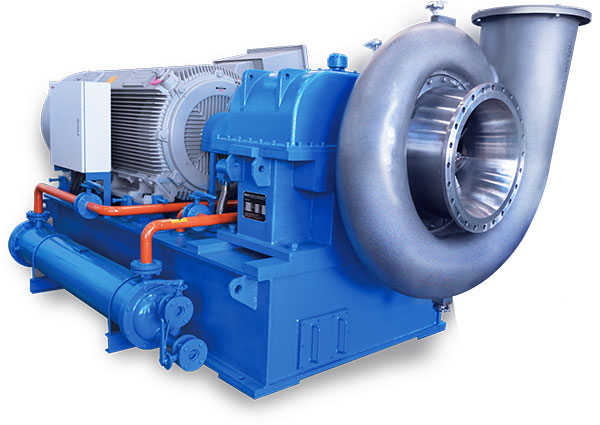

Centrifugal Turbo Compressor

Industrial Vapor Compression Solution

Centrifugal Steam Compressor is the core component of MVR (Mechanical Vapor Recompression) system. As the key component of the MVR system, steam compressor can improve the enthalpy of the secondary steam by compression of the secondary steam.

Through accurate calculation, accurate balance of investment and output ratio, our company design can obtain the reasonable processing capacity in evaporation system, fully utilize the function of the equipment, and achieve the best cost performance.

With leading technology, stable performance, and longer service life, LH Centrifugal steam compressor already reached the international advanced level.

LH Centrifugal Steam compressor is mainly used in pharmaceutical, food and beverage, chemical, sewage treatment, desalination and other industries.

LH steam compressor has following advantages:

- Adopt typical and mature motor & gear box & compressor structure, achieve high efficient, reliable operation, and simple maintenance;

- Compressor body is isolated from the atmospheric environment of the gear box, to avoid the steam pollution from the lubricating oil;

- Adopt the most advanced aerodynamic design platform, customization for each application, with higher accuracy, better compatibility and fast delivery.

Popular type compressors/blower details specifications comparison

| Popular type compressors/blower applied for MVR system | |||

|---|---|---|---|

| Type | High speed Centrifugal steam compressor | Low speed Centrifugal blower | Roots compressor |

| General features: |

|

|

|

| Details specifications comparison table | |||

| Temperature rise(℃) | 23~25 | 8~10 | 30 |

| Mass flow(m3/S) | ≥3 | ≥5 | ≤4 |

| Efficiency (%) | 80~85 | 75 | 60 |

| Impeller process method | Integral milling | welding | casting |

| Strength for rotary part | High | Low | High |

| Assembly accuracy | High requirement in bearing accuracy | middle | High requirement in Lobed rotor |

| Working stability | Better | Better | Not good |

| Working Noise | Lower | Lower | Higher |

| Maintenance | Better | Better | Not good |

|

Remarks for high speed centrifugal steam compressor: Remarks for Roots compressor: |

|||

Temperature rising and flow rate