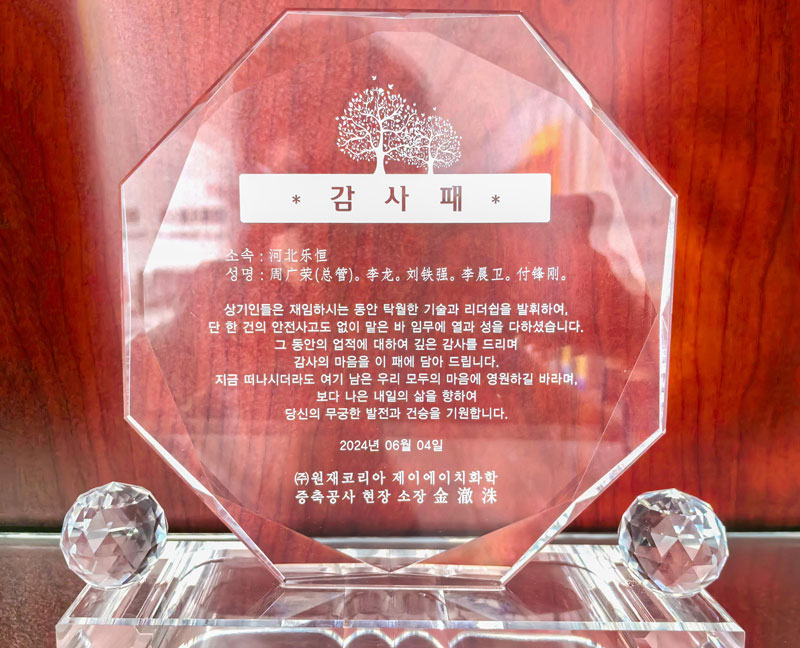

Recently, Leheng Energy Saving has won sincere gratitude and high recognition from a Korean battery recycling customer for our outstanding performance in overseas engineering projects. The medal specially awarded by the customer is not only an affirmation of the professional ability for Leheng team in project construction and management, but also an appreciation of Leheng's service attitude of striving for excellence.

In the 2,000-ton battery-grade lithium carbonate project, Leheng energy saving, as the EPC general contractor of the lithium carbonate workshop and by-product sodium sulfate system, provided the customer with full-process services including process design, equipment design, civil engineering and steel structure design and financing, equipment manufacturing, supporting equipment procurement, installation and commissioning, operation training, after-sales and tailored a one-stop turnkey engineering solution for this customer. During the execution of the project, the Leheng team relied on strict scientific management and efficient collaboration to ensure the smooth progress of the project with zero safety accidents.

In aspects of process flow, Le Heng relies on its rich experience in the field of MVR evaporation and crystallization, and effectively integrates the advantageous resources of Yaguang Co., Ltd. to provide a full-process solution for lithium carbonate production and by-product recovery, including evaporation crystallization, solid-liquid separation, powder processing, and drying and packaging. In particular, We uses Yaguang's Agitated Nutsche Filter Dryer filtering, washing and drying equipment as the core to optimize the lithium carbonate powder processing process, shortening the process flow for customers, improving product quality, and reducing operating costs.

In aspects of project management and engineering construction, Leheng has relied on its rich experience in implementing international engineering projects. From project approval to completion acceptance, we always adhered to high standards and strict requirements, upheld the spirit of craftsmanship of striving for excellence, fully implemented various measures for engineering quality management.

Faced with multiple challenges in overseas construction, Leheng team rose to the challenge, strictly followed the agreement with the customer to ensure the smooth installation and delivery of the project with professional project management and implementation capabilities, laying a solid foundation for future cooperation with this customer.

Leheng has always insisted on fulfilling our firm commitment to customers with practical actions, continuously innovating and practicing in the fields of pyrometallurgy, hydrometallurgy and powder process engineering of lithium battery positive and negative electrode materials, optimizing lithium battery industry solutions, keeping up with the national "dual carbon" strategy, practicing the concept of green development, and committed to providing customers with more efficient, high-quality, green and energy-saving solutions. Looking to the future, Leheng will continue to adhere to the "customer-centric" approach, continuously improve its international project management capabilities, and contribute more to the sustainable development of global energy.