The 16th International Battery Exhibition (CIBF 2024) was successfully held in Chongqing. Many domestic and foreign lithium battery upstream and downstream industry partners gathered together to exchange cutting-edge trends in industry development, share the latest technological achievements and application cases, and jointly explore the future of the industry in this three days’ event. Zhejiang Yaguang Co., Ltd., together with Leheng Energy Saving, Daliheng Powder and Huayi Engineering, bring their positive and negative electrode material pyrometallurgy, hydrometallurgy, and powder process engineering solutions at this exhibition.

Lay a solid foundation and base on the MVR core power technology

Over years, Leheng has been deeply involved in R&D and production. With MVR vapor recompression energy-saving technology as the core, We are continuously optimized and integrated the MVR evaporation and crystallization system together with upstream and downstream process equipment, and committed to the innovation of product technology and solutions. Focusing on crude lithium hydroxide, battery-grade lithium hydroxide, lithium carbonate, manganese sulfate, cobalt sulfate, nickel sulfate and other materials, Leheng has mature experience in MVR evaporation crystallization, vacuum continuous cooling crystallization, freeze crystallization and other processes. The use of MVR technology significantly reduces the use of steam during the evaporation and crystallization process, effectively helping companies reduce costs, increase efficiency, and improve market competitiveness.

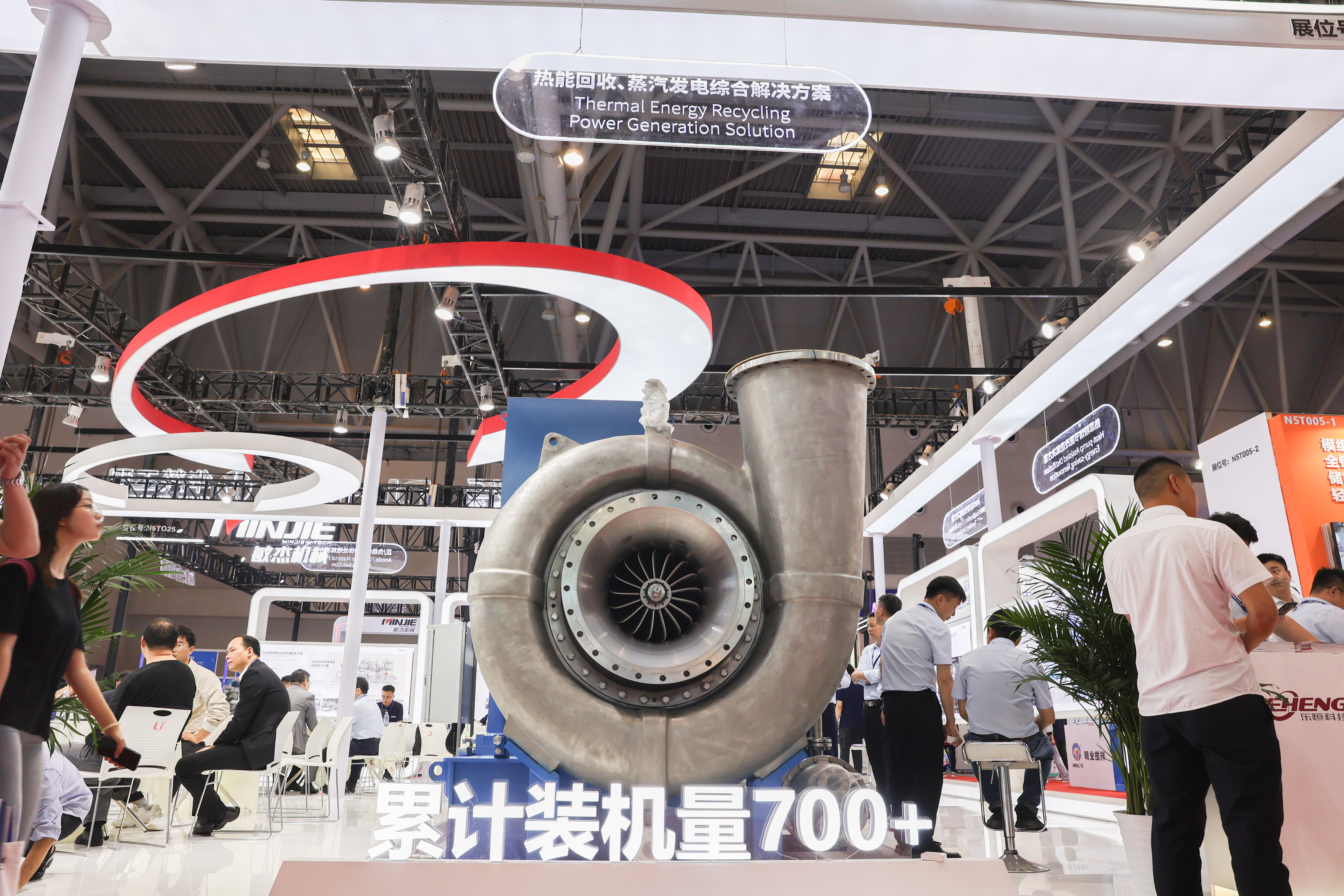

At the same time, Leheng has increased production and R&D investment in energy-saving transformation of traditional equipment and refined energy management, and has continued to make efforts in the fields of low-grade heat recovery, steam pressure reduction and cooling, steam heating and pressurization, high-pressure gas residual pressure recovery, and energy-saving transformation of process systems , aiming to help customers carry out overall energy-saving planning and build efficient and sustainable energy-saving solutions in recent years.

Steady progress and actively leverage the advantages of overseas projects

Leheng is not only advanced in production and manufacturing and strong process research and development capabilities, but also accumulated rich experience in engineering project. We can not only provide customers with one-stop EPC solutions, but also established long-term and in-depth cooperation with world-class engineering companies such as Wood , Hatch , TOYO , and LBT .

Leheng effectively integrated the resources from Yaguang Co., Ltd. and tailored a one-stop turnkey engineering service for customers to ensure the efficient implementation and smooth delivery in the Korean lithium carbonate battery recycling project.

In the lithium hydroxide production project of a lithium giant from Australia, Leheng worked closely with the engineering company to jointly advance to the project implementation stage.

Despite all above methods, Leheng also provide MVR evaporation and crystallization systems process design, equipment manufacturing, auxiliary installation, commissioning, and after-sales service.

In the future, Leheng Energy Saving will continue to actively leverage its technological leadership, increase investment in product research and development and application services, and provide customers with more high-quality and efficient new energy solutions. Starting from "new" and moving toward "green", we will build a green, low-carbon and sustainable energy systems actively contribute to a greener and more harmonious future.